March 27, 2020 | InBrief

How sales and operations planning enables a nimble supply chain

How sales and operations planning enables a nimble supply chain

The COVID-19 pandemic has created significant disruption to the lives of most consumers and well-established, profitable global organizations. The short- and long-term impact this virus will have on manufacturers and distributors is still being determined. However, their ability to pivot operations to meet new internal and external demands, including channel shifts and evolving customer behaviors, will play a large role in their success.

Adjusting to widespread and rapid market disruption can be extremely difficult and expensive. Even small disruptions, such as a major supplier declaring bankruptcy or a poor crop yield of a major component, have been known to create devastating and lasting consequences. However, these smaller-scale incidents can quickly be forgotten and written off. But the question remains: Why do organizations struggle to adapt in the short- and long-term when the market is suddenly disrupted?

The answer often lies with:

- The effectiveness of their supply chain planning function

- The communication strategy for key stakeholder groups

With irregular demand patterns and a high likelihood of potential supply interruptions, low-maturity planning organizations are almost completely reactive when they reach extreme levels of disruption. Reactive thinking and rushed decision-making become the requirement, with a narrow vision of longer-range consequences. This typically results in devastating, long-term actions to salvage immediate-term results, including reducing labor to match short-term reduction in demand.

Supply chain sales and operations planning (S&OP) can make the difference between success and failure during a market shift

Companies with a proper S&OP program in place not only have a better chance to survive the disruption but also to thrive among competitors. Market leaders such as Nike are optimizing their supply chains daily to remain flexible to changing market and customer demands.

A full S&OP program takes time to create, adjust, and perfect. It takes setting up a formalized mobilization plan, establishing a standard meeting cadence, creating cross-functional organizational plans, and enabling data-driven decision-making. Yet, aspects of S&OP can be implemented today to mirror a minimum viable product (MVP) approach that can quickly guide organizations through difficult times – limiting the need for new IT systems or organizational investments.

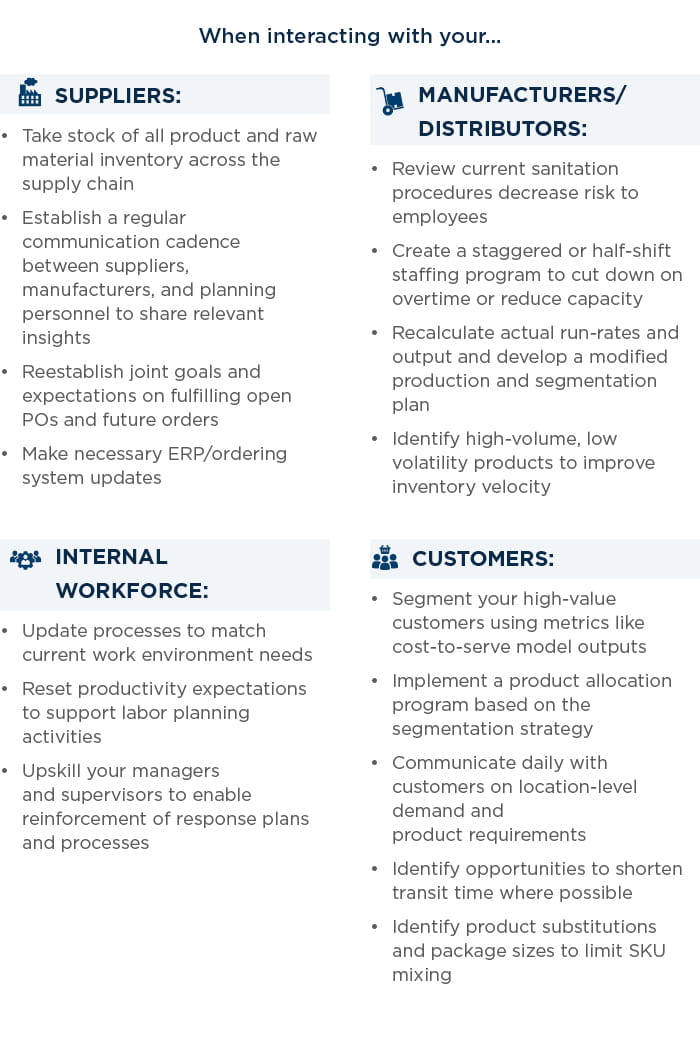

Each stakeholder group requires a specific strategy to enable efficient and connected operations. Here are a few actions to take with the supplier, manufacturer, internal workforce, and customer stakeholder groups to enable a supply chains to react and pivot to maintain healthy operations in both the short- and long-term.

A supply chain is complex; it involves multiple tiers of suppliers, organizations, and functions. It operates in an unstandardized, global landscape where a decision made within a single organizational point rarely can be traced and quantified within the enterprise-wide value chain. However, a renewed focus on the supply chain S&OP and key stakeholder communication strategy can help stem the short- and long-term impacts from unplanned market disruptions past and present.