October 2018 | Point of View

Flexibility and efficiency: Setting foodservice distributors apart

Delivery efficiency and flexibility to meet demands plays a critical role in shaping restaurants’ loyalty and decision making when sourcing food products

Delivery efficiency and flexibility to meet demands plays a critical role in shaping restaurants’ loyalty and decision making when sourcing food products.

Introduction

Restaurants have long had many choices when selecting potential food suppliers. Now, with the expansion of retail grocery delivery services, foodservice distributors are challenged to become even better at meeting restaurants’ expectations for quality, price, reliability, and customer service.

In a recent survey completed for West Monroe, restaurant operators were questioned about the aspects of their foodservice distribution relationships that impact satisfaction and buying decisions. Several themes emerged from these discussions—top among them was the need for providers to focus on delivery efficiency and flexibility to meet shifting demands.

Chapter 1: Restaurants navigate a wide (and growing) array of food supply choices

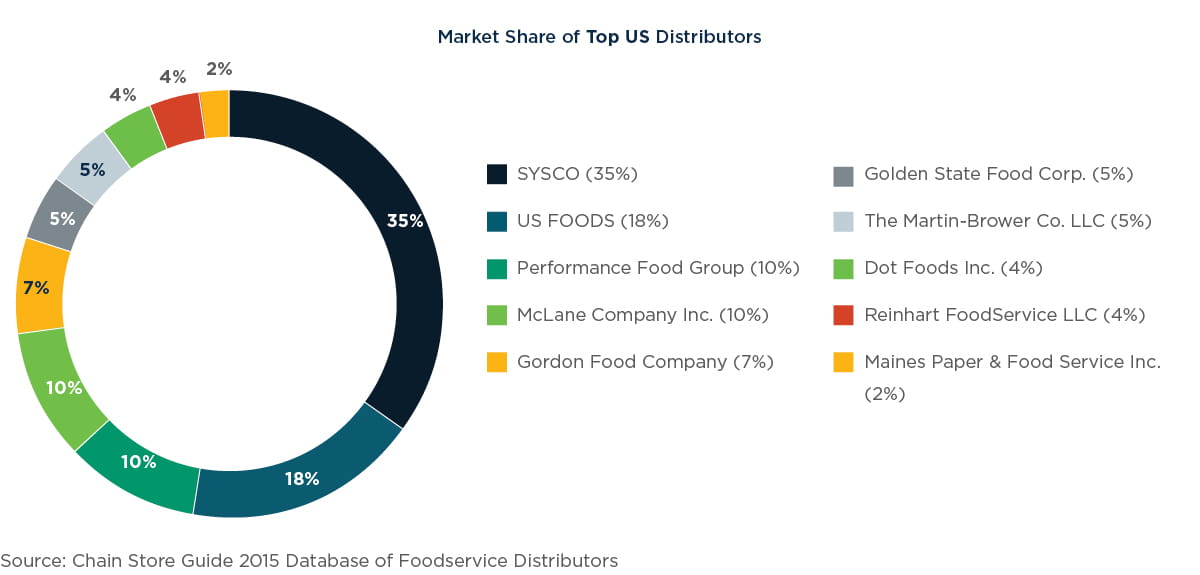

The U.S. foodservice distribution industry comprises a handful of large national competitors and many small and regional organizations—all vying for a share of restaurant business. According to reports, there are approximately 16,500 companies in the foodservice distribution industry1. While the top 10 foodservice distributors account for a significant share of the market, smaller distributors represent a cumulative majority of the industry.

In addition to traditional foodservice distribution sources, restaurants also have access to wholesale sources, such as Costco and Sam’s Club, as well as retail suppliers, such as Amazon and national grocery chains that are getting into the delivery business. Industry researcher Technomic estimates that the wholesale market accounts for about 10% of the $268 billion foodservice supply chain2. Its research suggests that restaurant operators buy from two to three broadline and six to seven specialty distributors in order to achieve a balanced supply of selection, quality, and price. This means that it is common to find a restaurant owner or manager spending 10 to 15 hours per week on purchasing.

Given the array of potential choices, we wanted to gain insight into the important factors in a restaurant’s decision to select its foodservice providers. To do so, we commissioned a survey with the University of Illinois College of Business’ Illinois Business Consulting (IBC) organization.

Chapter 2: Delivering on restaurants’ most important selection criteria

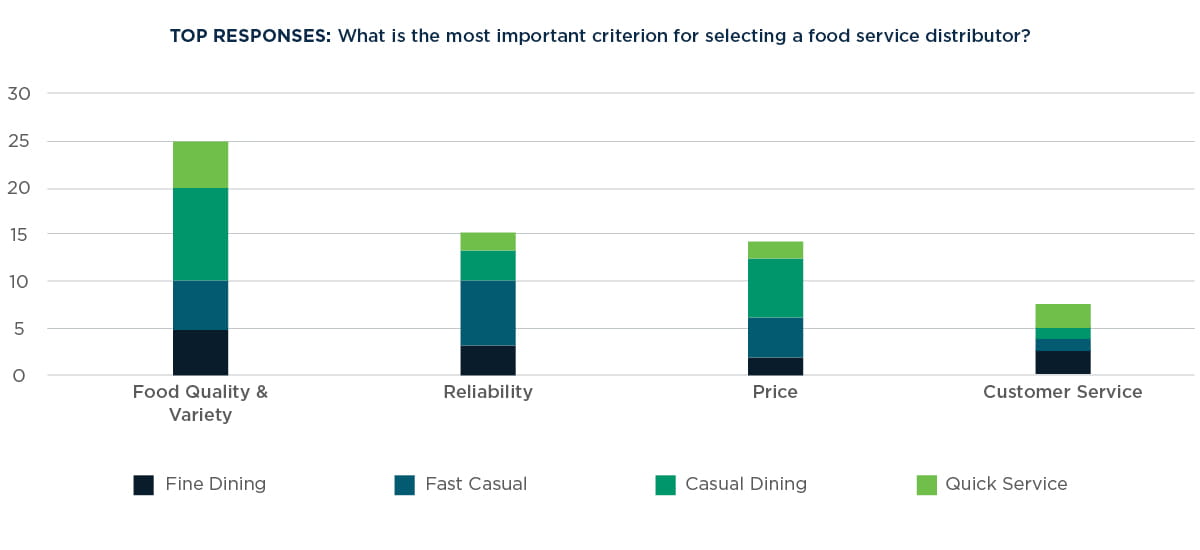

What do restaurants cite as their most important criteria for selecting a foodservice distributor? Predictably, quality and price were among the top four responses.

Knowing that most providers are already working to deliver the highest quality food at a reasonable price, we wanted to dig deeper into the other two leading factors that drive restaurant decisions: reliability and customer service. Through interviews, we asked restaurant operators and managers to elaborate on their expectations and common concerns. Two themes emerged from these discussions: delivery efficiency and the flexibility to meet demands.

Chapter 3: Improving delivery efficiency

Improving delivery efficiency requires evaluating both how providers deliver orders and how restaurants receive orders and optimize their systems.

From the restaurant’s perspective, the most efficient method is the after-hours key drop because it doesn’t interfere with normal operations. Many restaurants, however, are not willing to provide after-hours access due to security policies or a desire to inspect deliveries as they are received. In the event of quality issues or missing cases, a restaurant would not be able to report the issue until the next business day, delaying delivery of what could be an essential ingredient.

This leaves the option of live delivery. Since only restaurants with very large orders receive full pallet drops, the delivery process can be highly variable, taking anywhere from a few minutes to over an hour depending on the quantity and ease of delivery. This process occupies a restaurant employee who otherwise would be focused on normal activities. While a restaurant is not required to inspect every shipment prior to receipt, many survey respondents said they prefer to do so while the driver is still there so they can resolve issues right away.

In other words, the customer who wants efficient delivery has a direct impact on that process.

Here are important steps for improving delivery efficiency:

Send a right-sized vehicle for the neighborhood.

Sending a large truck to a busy urban environment with limited access slows down the entire process, since the driver may not be able to park close to the stop. This increases the time for each trip from the truck to the stop and also limits the window for delivery if heavy traffic is a concern. Utilizing smaller, more agile vehicles can reduce delivery times while also operating at a lower cost-per-mile than larger vehicles.

Pack deliveries methodically to minimize driver re-handling.

This can be done by securing multiple delivery items going to the same location together using totes, bags, or case straps. This will allow the drivers to pick the deliveries up in one motion rather than handling each one individually. This may require more time for loading a delivery vehicle, but if driver wages are higher than warehouse wages, then the savings in driver time will offset the upfront cost. This also reduces the amount of time the customer spends receiving the delivery, which can affect satisfaction.

Use technology to increase delivery accuracy.

Many foodservice distributors already scan each case at the point of delivery. This provides a much more accurate delivery record than using a paper manifest. This method also improves customer confidence that they are receiving the items and cases ordered, however, it does not alleviate concerns about receiving damaged or poor-quality items. One possible solution is to use a scanner with a camera. The camera can be set to take a picture of each case as it is scanned.

If the customer has a concern about quality or damage, both the customer and distributor can review the photo to reach a quick resolution. More importantly, this approach helps the distributor track, understand, and address quality or accuracy issues promptly and keep customers happy.

Review accuracy of the planned driver day.

Inaccurate plans can lead to missed delivery windows, causing customer frustration and increasing the cost to both the customer and the distributor if the new delivery time does not meet the customer’s schedule or local traffic patterns. Using engineered driver standards can increase the accuracy of the planned day by making sure the time allocated for each stop is representative of the actual delivery time.

Once a distributor has established a realistic time for each stop, it then can develop the optimal routing. The best routing solutions use predictive models that consider normal delays for a particular route.

For example, if a route has several stops in the city, it will schedule these at a time that is not during rush hour. Other attributes include real-time adjustments for unexpected traffic delays, such as accidents or construction. Combining engineered standards with accurate routing improves delivery window estimates and increases customer satisfaction.

Chapter 4: Flexibility to meet a variety of delivery needs

In our survey, many restaurants expressed the importance of being able to order small amounts of items as needed and have them delivered quickly at a reasonable cost. To address this, many large distributors have established minimum order quantities to reduce the number of costly, inefficient small-quantity orders. To enable agile demand response, they instead allow restaurants to order less than the minimum quantity for a premium or penalty. Often, the customer must pick up the order at a distribution center, but this still provides the option to purchase that small-quantity order.

Historically, customers have not had many alternatives to paying this premium, other than running to a supermarket. This can be time-consuming, and it typically takes a valuable resource away from a well- run kitchen. With the introduction of services such as Kroger’s ClickList or Giant Eagle’s Curbside Express, restaurants can place orders online and pick them up within a couple hours, eliminating time spent shopping in the store. Grocery delivery services, such as Amazon Fresh or Peapod, take this option one step further by providing doorstep delivery.

Given the growing array of alternative sourcing for restaurants, foodservice distributors must find a way to meet demands while still controlling operating costs. Because restaurants define demand, this starts with customer expectations. Following are several steps for aligning services to expectations.

Make it easy for restaurants to place orders, big or small.

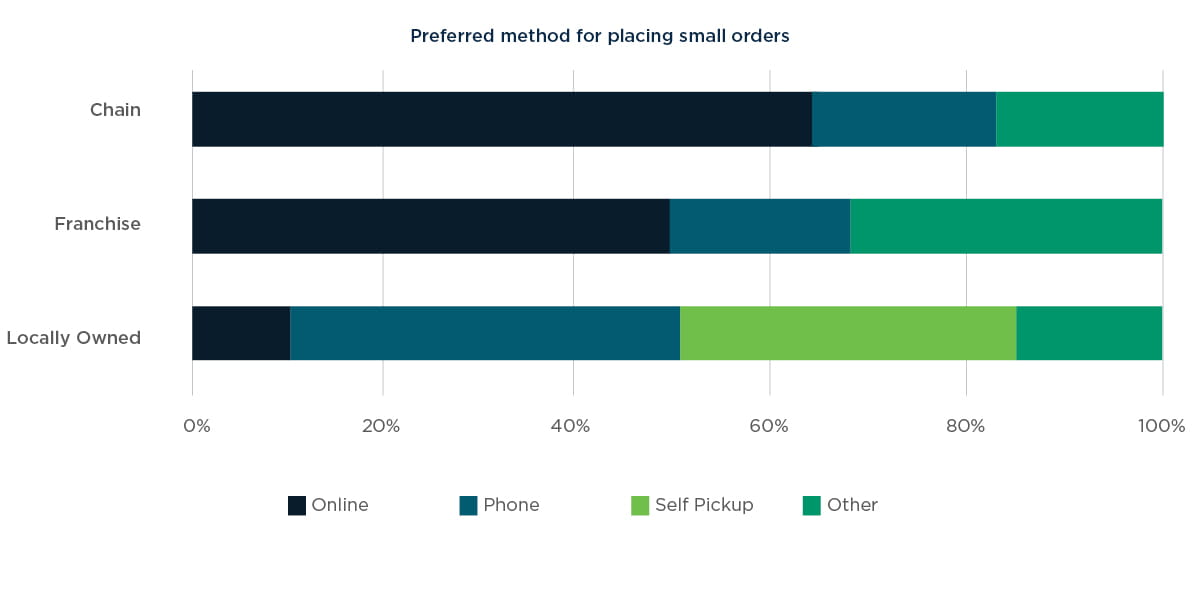

Our study examined how restaurants prefer to place orders for small quantities. For example, while chain and franchise restaurants favor online ordering, locally owned restaurants expressed a preference for ordering by phone rather than online because it is easier and more flexible for small orders. This finding suggests that while foodservice distributors may have a phone ordering option already in place, they should also review their online ordering systems to find ways to make them more user-friendly and easier to navigate.

Online ordering is not only important to many restaurant customers, it also provides the quickest and most cost- efficient order processing option for distributors, and reduces the chance of an incorrect order due to data entry errors or miscommunication.

Provide easy access to orders and status.

In our survey, restaurant operators said that, once they place an order, they want to be able to track it at every step and make changes as necessary. Many large distributors already have mobile applications in place, and in the future, conversational technologies—chatbots and virtual assistants—will enable restaurants to order food products, manage orders, review invoices, and check delivery status.

Use available data to understand the true cost of serving customers.

It is not enough to track cost by order or client. Rather, developing an accurate cost-to-serve model requires tracking the labor, overhead, and equipment costs associated with each step of the process. As the industry relies more on technology, distributors are capturing such data at every point in the supply chain, from initial sales call or order to the final point of delivery.

Analyzing this amount of data can be a challenge, particularly for distributors that use multiple systems for different functions—for example, separate systems for order management, warehouse management, labor management, and transportation management. In these cases, having a platform in place to consolidate all of this data into one usable environment can make a difference between making informed decisions based on data models or poor decisions based on assumptions and incomplete analysis.

The ability to analyze data makes it easier to understand the cost variability associated with different types of deliveries. This insight is essential for increasing flexibility around demand.

Leverage cost insight to establish a variable pricing model.

One potential result of complete and accurate data is the ability to create a cost model enabling variable pricing—akin to Uber’s “surge” pricing—depending on key inputs such as item, quantity, delivery address, or delivery time. If a restaurant demands a product for the evening dinner rush and the delivery will take place during rush hour, then the distributor can charge a higher price than it does for a restaurant that orders in the middle of the day when there is less congestion. On the other hand, if the restaurant is in an area where the distributor already plans to send a driver, the distributor can offer a reduced rate because it is part of a denser, and therefore more efficient, delivery route.

Conclusion

Today’s restaurants have an array of sourcing choices, both traditional and emerging, putting the onus on distributors to examine and modernize their operations to appeal to the relationship characteristics that restaurants value the most.

According to our survey, delivery efficiency and flexibility to meet demands plays a critical role in shaping restaurants’ loyalty and decision making when sourcing food products. To address these areas effectively, foodservice distributors will need to establish a high degree of synchronization among internal technologies, customer solutions, analytical tools, the sales engine, and operations. Investing in one of these areas while neglecting others could upset the balance, affecting customer satisfaction. On the other hand, foodservice distributors that approach delivery efficiency and demand flexibility strategically will find themselves well positioned for strong, long-term relationships with their restaurant customers.